Vacuum technology has quietly revolutionized industries, enabling advancements in manufacturing, healthcare, electronics, and scientific research. But what exactly is vacuum technology, and why is it so critical in today’s world? In this blog post, we’ll explore its fundamentals, applications, benefits, and future trends—all while keeping SEO optimization in mind with natural keyword integration.

Understanding Vacuum Technology: The Basics

At its core, vacuum technology involves creating and maintaining a space devoid of matter, particularly air or gases. This is achieved using specialized equipment like vacuum pumps, chambers, and gauges. The level of vacuum is categorized into ranges:

- Low vacuum: Common in household appliances like vacuum cleaners.

- Medium vacuum: Used in industrial processes such as freeze-drying.

- High vacuum: Essential for semiconductor manufacturing.

- Ultra-high vacuum (UHV): Critical in advanced scientific research, like particle physics.

The ability to control pressure environments has made vacuum systems indispensable across sectors. By removing contaminants, managing gas reactions, or enabling precise material deposition, this technology drives innovation.

Applications of Vacuum Technology Across Industries

1. Manufacturing and Electronics

Vacuum technology is the backbone of electronics production. For instance, semiconductor manufacturing relies on high-vacuum environments to deposit thin films on silicon wafers without contamination. Similarly, vacuum furnaces are used to create high-strength metals and alloys for aerospace components.

2. Healthcare and Pharmaceuticals

In healthcare, vacuum systems sterilize medical instruments and preserve sensitive medications through lyophilization (freeze-drying). Vacuum pumps also power MRI machines and suction devices in surgical settings, ensuring precision and safety.

3. Energy and Sustainability

Renewable energy sectors leverage vacuum tech for solar panel production. Thin-film solar cells, for example, require vacuum deposition to enhance efficiency. Additionally, vacuum insulation panels (VIPs) improve energy retention in buildings, reducing carbon footprints.

4. Scientific Research

From particle accelerators to space simulation chambers, ultra-high vacuum environments allow scientists to study matter under extreme conditions. This has led to breakthroughs in materials science, quantum computing, and astrophysics.

Why Vacuum Technology Matters: Key Benefits

- Precision and Control

Vacuum systems eliminate variables like oxidation and contamination, ensuring processes like coating, welding, or chemical synthesis occur with unmatched accuracy. - Enhanced Product Quality

In food packaging, vacuum sealing extends shelf life by preventing bacterial growth. In electronics, it ensures microchips function flawlessly. - Energy Efficiency

Vacuum insulation and industrial processes reduce energy consumption, aligning with global sustainability goals. - Cost-Effectiveness

By minimizing waste and improving production speed, vacuum solutions lower operational costs for businesses.

Challenges in Modern Vacuum Systems

While vacuum technology offers immense benefits, it’s not without hurdles:

- Maintenance Costs: High-vacuum pumps and chambers require regular upkeep.

- Complexity: Achieving ultra-high vacuums demands advanced materials and expertise.

- Energy Use: Some systems consume significant power, though innovations are addressing this.

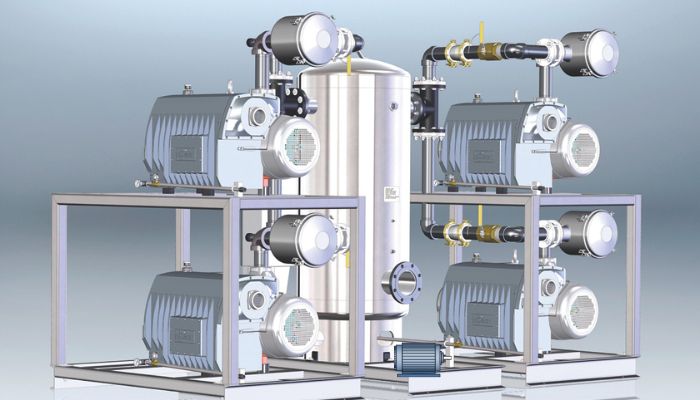

Thankfully, advancements like dry vacuum pumps (which eliminate oil contamination) and smart sensors for real-time monitoring are mitigating these challenges.

The Future of Vacuum Technology: Trends to Watch

1. Smart and IoT-Enabled Systems

Integrating IoT sensors into vacuum equipment allows predictive maintenance, reducing downtime. For example, a smart vacuum pump can alert users about filter replacements or pressure drops.

2. Green Innovations

As industries prioritize sustainability, energy-efficient vacuum pumps and recyclable materials for vacuum components are gaining traction. Companies are also exploring hydrogen-compatible systems for clean energy applications.

3. Miniaturization

Compact vacuum systems are emerging for portable medical devices and small-scale labs, democratizing access to high-precision technology.

4. Space Exploration

NASA and private aerospace firms use vacuum chambers to simulate space conditions, testing equipment for missions to Mars and beyond. This synergy between vacuum tech and space research will only grow.

Choosing the Right Vacuum Solution for Your Needs

Selecting a vacuum system depends on factors like:

- Pressure Requirements: Match the vacuum level (low, high, UHV) to your application.

- Industry Standards: Healthcare and food processing demand compliance with strict hygiene norms.

- Budget: Balance upfront costs with long-term savings from energy efficiency and durability.

Consulting with vacuum technology experts can help tailor solutions to your specific goals.

Conclusion: Embracing the Power of Vacuum Technology

From producing life-saving medicines to enabling space exploration, vacuum technology is a cornerstone of modern innovation. As industries evolve, so will the demand for smarter, greener, and more efficient vacuum systems. By understanding its applications and staying ahead of trends, businesses and researchers can unlock new possibilities.